Our place in the Circular Economy

We explore the Circular Economy as it applies to Waste and Recycling companies, and look at ISB Global’s place in offering relevant waste management & recycling software solutions.

We explore the Circular Economy as it applies to Waste and Recycling companies, and look at ISB Global’s place in offering relevant waste management & recycling software solutions.

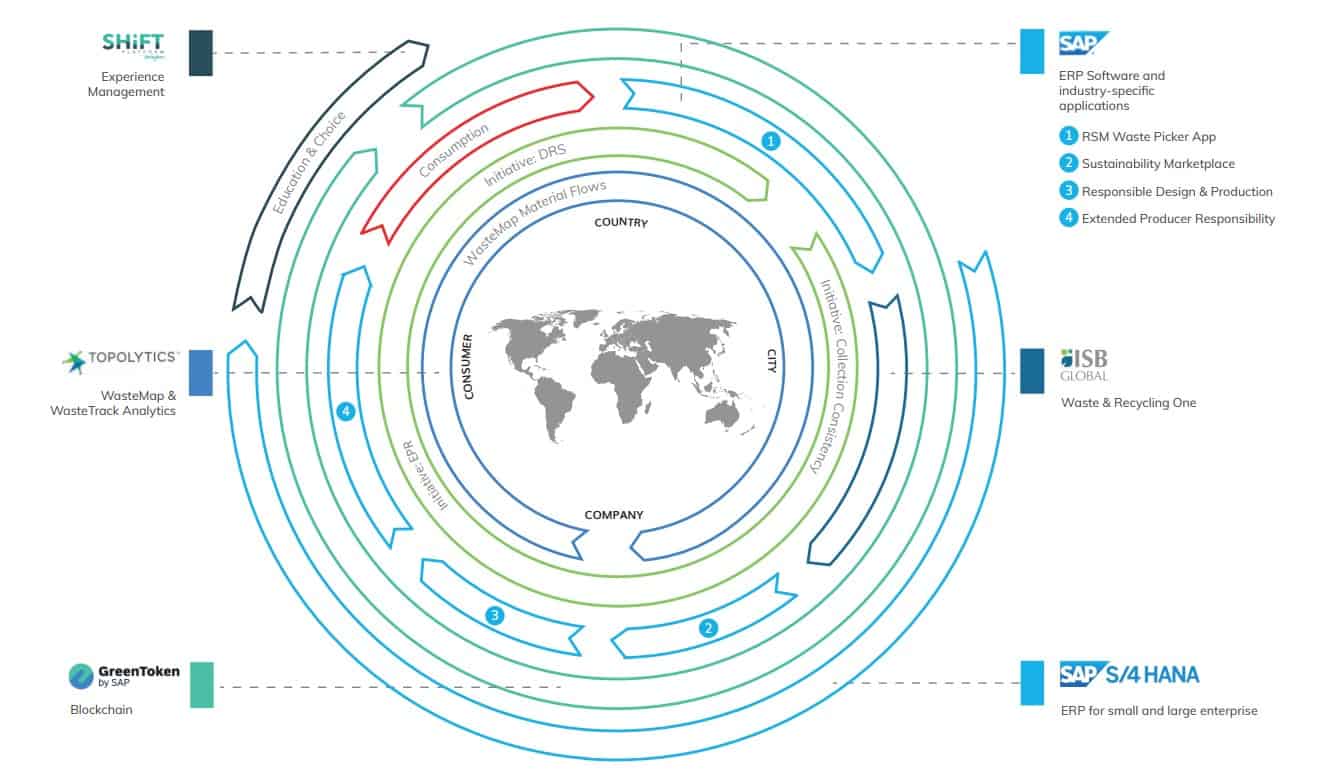

The Zero Waste Business Network describes a portfolio of companies, including ISB global that together can manage a circular economy. The network is made up of SAP, ISB Global & Partners, who together offer a unified system of software applications, technologies and industry expertise.

Using technology for waste and recycling management to reduce the climate emergency →

There is a problem. The world cannot continue to consume materials at the current rate. The waste crisis is contributing to the climate crisis. Waste materials leak into the land and oceans poisoning life on earth. SAP and partners are committed to resolving the problem. As 77% of the world’s transactions touch an SAP product and SAP are the largest business management software company in the world, SAP are well positioned to help solve the challenge. Collectively we can offer a solution to the emergency and contribute to provide a resolution to the most pressing challenges in managing a circular economy and circular supply – The Zero Waste Business Network.

Sustainable Waste Management and Recycling solutions from SAP →

The Zero Waste Business Network here shows where ISB Global’s WR1 Solution fits within the overall products and services that are enabling sustainable business operations. It includes trusted Partner’s Solutions that ISB Global can work with, to offer you a complete solution.

As part of the SAP Sustainability Management portfolio of products, the Zero Waste Business Network is a suite of modular applications that incorporates multiple SAP, partner software products, partner intellect and market knowledge. This unprecedented collective of expertise inspires towards a circular economy. Managing product and material design, sourcing, production, consumption, recovery and reuse, logistics, transport and finance.