Across the world, the linear economy model means that we waste too much. From food waste to electronic waste, too much of the things we consume end up in landfill, or in our rivers and seas. If we want to move to a circular economy model, we need to close the loop that is waste.

There’s been a lot of research on both models to help close the various waste loops that exist, and the technologies that enable us to get there. In fact, technology is critical to establishing a sustainable circular economy.

Technology helps us understand the current position. It helps us monitor material sourcing, production processes, packaging, transportation and use. Improving all those areas, including managing products at the end-of-life stage to reuse and redesign wherever possible to prevent unnecessary waste.

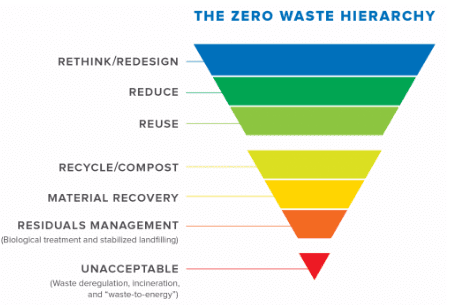

Here’s a reminder of the zero waste hierarchy – which underpins the drive towards a circular economy.

End-to-end considerations

To commit to a circular economy approach, organisations need to look at their key processes. The Close The Loop framework sets out seven stages to consider:

- Resources

- Design

- Production

- Retail

- Consumption

- End of life

- Systems thinking

By using technology to collect and monitor data across these areas, organisations can get useful insights on current operations. This allows them to see where and how they could improve to reduce waste, become more efficient or change processes to manage operations better.

Many companies don’t have the technology to get this visibility. With a number of legacy systems, including Excel spreadsheets and even hand-written documents, it can be impossible to find that clarity.

So your first step towards a circular economy model in your business is to update your technology so that your data is centralised, visible and useful.

Slowing the loop or closing the loop?

Of course, if you could close the waste loop overnight, we’d have much less to worry about. It’s certainly possible to make changes that have an immediate impact, but in many cases, organisations need to focus on ‘slowing’ the loop, rather than closing it. By adopting a clear model to face these challenges, organisations can start to slow the loop, which is often the first step to closing it.

The Ellen McArthur Foundation has developed the ReSOLVE model. ReSOLVE is:

- Regenerate

- Share

- Optimize

- Loop

- Virtualize

- Exchange

This model can be applied to all the stages in the Close the Loop framework to help organisations see how they can make measurable progress. To do this, it’s important to adopt or invest in innovative technologies.

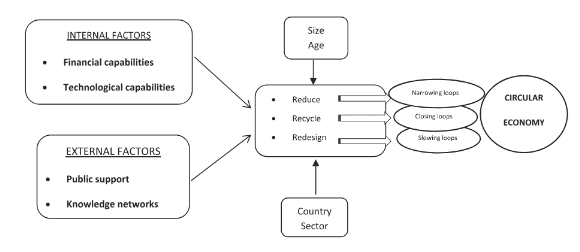

A 2022 paper, Closing the loop through eco-innovation by European firms: Circular economy for sustainable development, (Triguero, Cuerval and Sáez-Martínez), is available on the website Wiley.com – business strategy and the environment. The paper includes the diagram below:

This shows three methods that can contribute towards a circular economy within an organisation.

Narrowing the loop

The principle of ‘reducing’ is about narrowing the loop. It looks at how to reduce waste across the board – from the energy used in mining raw materials to designing better packaging. Where organisations can reduce waste in their processes, or adopt circular economy technologies like using recycled materials instead of new raw materials, they should do so.

Technology plays a key role here too. Businesses may choose to switch to sustainable or renewable energy to power their facilities. They may work with secondary markets to buy materials that have been repurposed from waste products. They may look at technologies that allow them to reuse or repurpose their own products when they get to end of life.

Closing the loop

In this model, ‘closing’ the loop is about being able to reuse and recycle all elements of the product. The aim should be to get to a zero waste position, but this may take time, so businesses should set targets for various stages of closing their resource loops. That way, they can measure and report progress, communicate with stakeholders and have a strategic plan for change.

This sounds great, but can be tricky to manage in practice. You’ll need to work with a waste collection and recycling partner that can collect, separate and treat your products to provide you with the materials you need to put back into your production process. You’ll also need to be able to monitor the processes so that you can report accurately. All of this requires intelligent technology to keep your circular processes moving.

You may also want to adopt more efficient energy consumption practices, and use technology to change your current production processes to accommodate recycled components.

Slowing the loop

Transitioning to a circular economy model is an investment – both in time and money. You may not be in a position to either narrow or close the waste loops in your business straight away, but there are always ways to improve.

This is where ‘slowing’ the loop comes into play. This is essentially about redesigning your products so that they contain fewer waste materials, or have a longer lifespan or are easier to maintain and repair. You may also want to think about redesigning your processes to use less energy, be more efficient, or optimise transportation and fuel consumption. Any changes you make will be a starting point on your journey to a circular economy. Starting to consider the right technologies at this stage will put you in a stronger position as you move to more structured or in-depth changes.

At ISB Global, we believe in the power of technology to support companies towards a circular economy model. Our waste and recycling solution, Waste and Recycling One is specifically designed to help companies in this sector to improve visibility over their data, manage processes more efficiently and support their clients to manage their own transition.