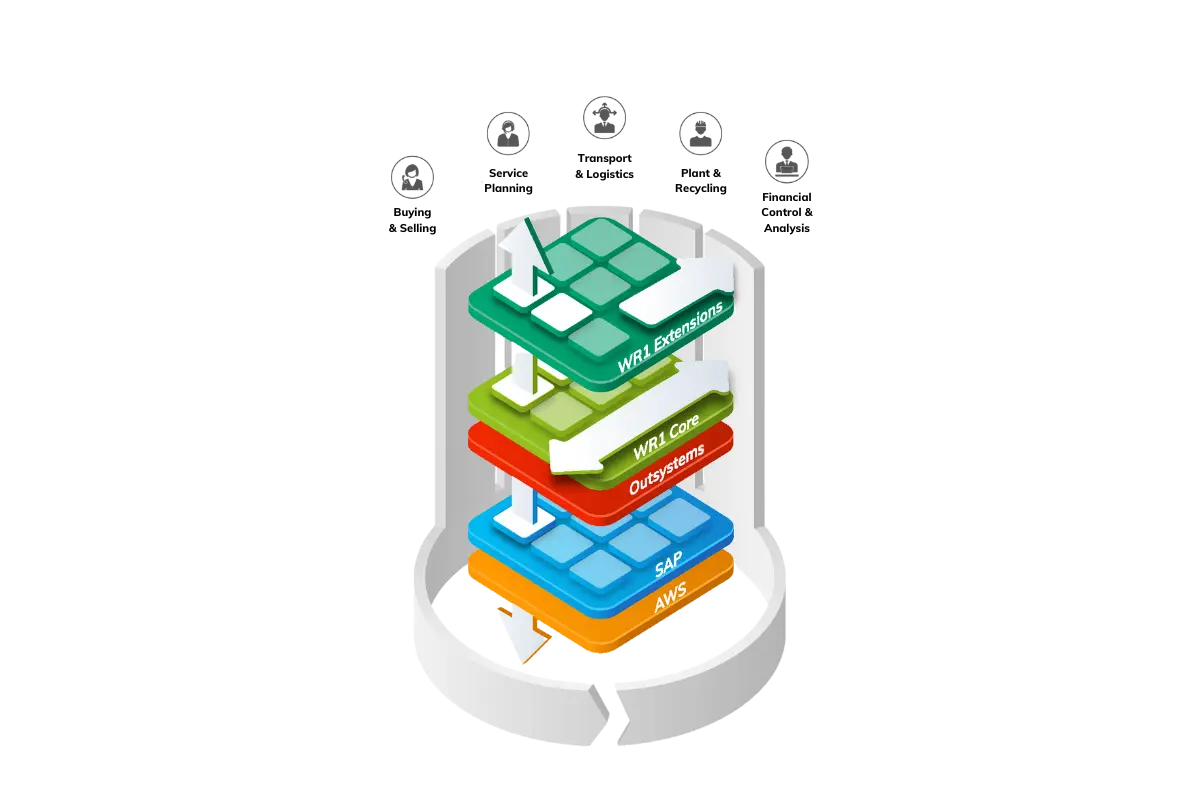

Buying and Selling

WR1 brings together all buying and selling activities, including CRM, SRM, Enquiries and Quoting. This means a very efficient and effective management of the Customer & Supplier acquisition process as well as their ongoing management, in a full or partially self-service way. This all leads to a seamless operational process right through to billing with the reassurance that nothing is getting dropped or missed.

Service Planning

Whether you are buying or selling materials & services, WR1 ensures that everything is automatically updated and processed. Leading on from the Buying and Selling process, the resulting Contracts, Pricing and Service Areas are all held and managed with strict controls and simple to use workflows. This means your customers, suppliers, and staff will always know what services are available, across all locations, at any time. Planning services and collections becomes easier and accurate, leading to improved profit and customer satisfaction.

Transport & Logistics

When your regular services are generated, the integration and automation in WR1 brings huge efficiencies in planning, scheduling, routing optimisation and driver management. Everyone can clearly see what needs to be done and when; and changes can be recorded instantly, even from the road, so your people can adjust schedules and routes as needed. If you don’t have your own vehicles, then you can still manage your third parties in the same way.

Site & Recycling Operations

After the logistics processes are complete, the efficiencies WR1 creates are crucial when it comes to ensuring weighbridge, materials management, plant control and reporting is accurate and integrated with Stock and Billing Management,. You’ll see profits rise as plant and recycling operations become smoother ensuring more of your material is quickly and accurately brought & sold.

Financial Control & Governance

The icing on the cake is that WR1 understands what is required to make a business profitable, and prides itself in reporting ‘One Version of the Truth’ . Unlike any other software on the market today, Waste & Recycling One delivers instant control and complete visibility across your entire waste management and recycling operations. You can plan, track, capture, analyse, and report on all aspects of the business, knowing the data is accurate and up to date.

Data & Analytics

WR1 understands the importance of data and analytics in driving process automation, resource efficiency, compliance, and overall profitability. Waste & Recycling One offers an integrated 360 view of operations and finance, allowing you to make informed decisions based on real-time insights.